Who are we?

NSI Microscopy Inspection Automation Ltd.

We automate conventional microscopy inspection.

What if we could take your microscopy process and turn it into something more efficient and less time consuming. This would save resources, space, time and would give you the opportunity to continuously improve your process.

What if we could take your microscopy process and turn it into something more efficient and less time consuming. This would save resources, space, time and would give you the opportunity to continuously improve your process.

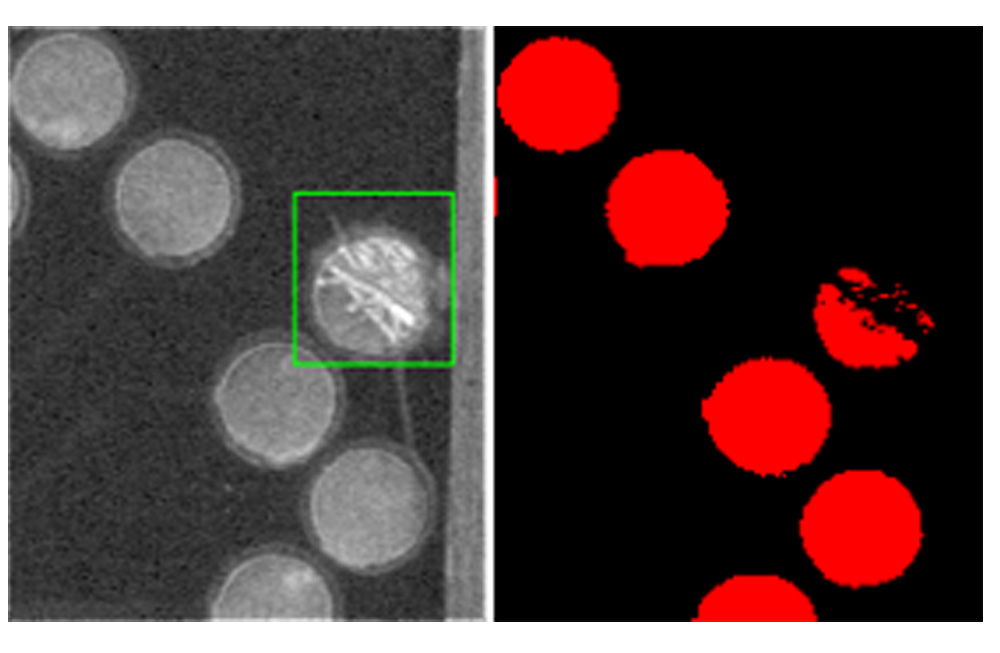

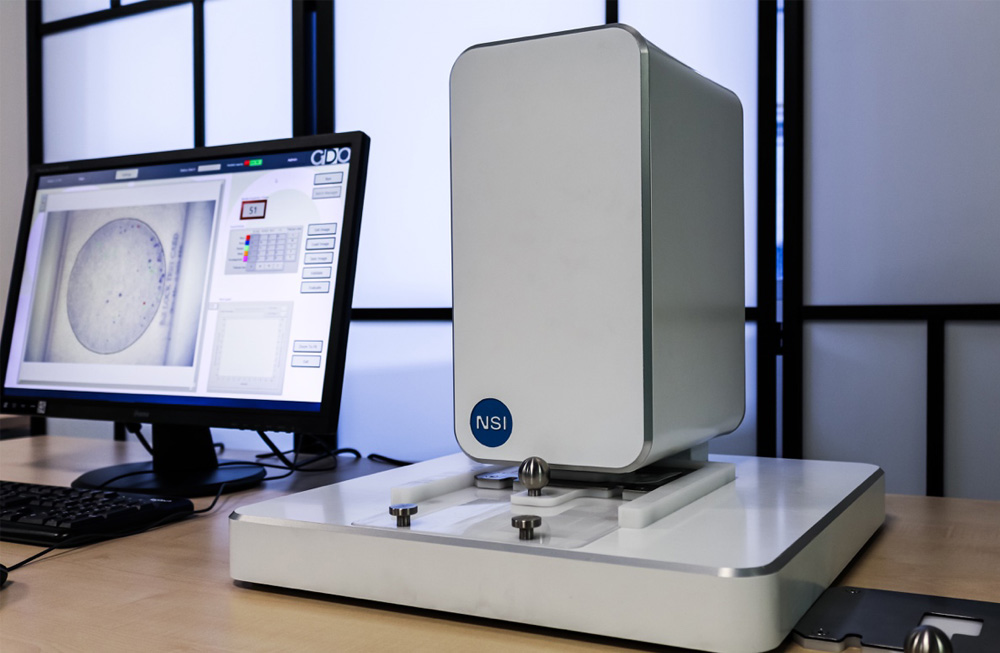

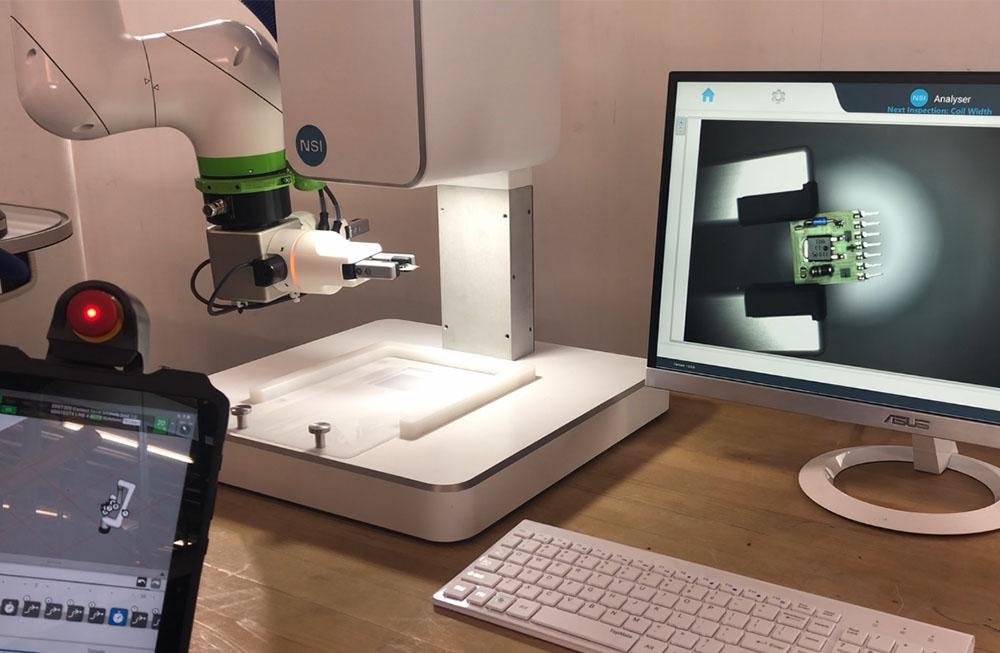

NSI Microscopy is a configurable software assistant, designed by GDO BV, and is based on 30+ years of proven microscopy inspection technologies. SMART tools are used to support operator activities, reduce process variation, and reduce cycle times. NSI microscopy provides conditional hardware and services but could also reuse your existing equipment.

If you have a potential project, then there are some easy steps that we follow together. First, we want to listen and understand your process, because this is key. Second, we will configure the software to match your process. And three, we advise on hardware and services. We strongly believe that you should be able to get everything out of one hand, which is why we will support you from the initial idea to an implemented and functional application.

If you have any questions, please don’t hesitate to contact us through our website. Or just drop us an e-mail at: info@nsi-microscopy.com

NSI Microscopy Inspection Automation We’re fast, are you?

Request for more information